Why Construction Site Sediment Control Matters

Construction site sediment control is essential for preventing soil erosion and protecting water quality during building projects. Without proper controls, your site can literally wash away, causing environmental damage, regulatory fines, and costly project delays.

Key Construction Site Sediment Control Methods:

- Silt fences: Install around the perimeter of disturbed areas to filter sediment from runoff

- Sediment basins: Use for drainage areas between 5-100 acres to collect and hold sediment-laden water

- Fiber rolls: Place along contours to slow water flow and trap sediment on slopes

- Inlet protection: Shield storm drains from sediment with filters or barriers

- Stabilized entrances: Install rock pads at site entrances to prevent tracking mud onto roads

Runoff from construction sites is by far the largest source of sediment in urban areas under development. When rain falls on exposed soil, it can wash away at rates of 7-1,000 tons per acre per year—dramatically higher than the less than one ton per acre per year from undisturbed areas. This not only damages your project but also harms nearby waterways and can result in significant fines.

In central Indiana, our clay-rich soils and intense seasonal storms make effective sediment control even more crucial. The good news is that with proper planning and implementation, you can protect your investment while meeting all regulatory requirements.

I’m Clay Hamilton PE, President of Patriot Excavating with over two decades of hands-on experience implementing construction site sediment control measures throughout Indianapolis and central Indiana. My background in site development has taught me that proper sediment management is not just about compliance—it’s about protecting your investment and our community’s resources.

Ready to ensure your next project has proper sediment control from day one? Contact Patriot Excavating today for a consultation with our experienced team.

Construction Site Sediment Control Essentials

When the skies open up over central Indiana, your construction site can quickly turn from a well-organized workspace into a muddy mess. But the consequences go far beyond dirty boots and delayed timelines.

According to EPA research, construction sites typically produce 10 to 20 times more sediment than agricultural lands—a startling figure that hits home here in Indiana where the White River and its tributaries serve as lifelines for communities from Noblesville to Martinsville.

The Clean Water Act established the National Pollutant Discharge Elimination System (NPDES), which requires permits for any construction that disturbs one acre or more. This one-acre threshold is your federal baseline, but don’t be caught off guard—many local ordinances in Carmel, Fishers, and throughout the Indianapolis suburbs enforce even stricter requirements for smaller sites.

“Runoff from construction sites is by far the largest source of sediment in urban areas under development,” the EPA notes in their construction stormwater guidance. This reality is why thoughtful planning before the first excavator arrives can save you significant headaches later.

Your site’s sediment control needs aren’t one-size-fits-all. They’re influenced by several key factors:

Slope length and steepness dramatically impacts runoff velocity—the steeper and longer your slopes, the more soil particles water can carry away. Rainfall intensity matters too, especially with central Indiana’s notorious summer thunderstorms that can dump inches of rain in just hours. Our region’s clay-rich soils present unique challenges once disturbed, while the size and duration of your soil exposure directly correlates to your environmental risk.

Poor sediment management reaches far beyond your property boundaries. When not properly controlled, sediment can clog storm drains in Plainfield and Avon, fill retention ponds in Brownsburg and Danville, and degrade water quality throughout our local waterways—potentially leading to costly fines and restoration requirements.

Where Does All That Mud Come From?

Drive past any active construction site in Greenwood, Franklin, or anywhere in central Indiana, and you’ll spot several common sources of potential sediment runoff that demand careful management.

Topsoil stripping creates the first major vulnerability. When we remove the protective blanket of vegetation that naturally shields soil, we expose it directly to rainfall. Each raindrop hits with surprising force—like tiny water bombs—dislodging soil particles and setting erosion in motion. As the Massachusetts Department of Environmental Protection explains, “When vegetation is removed, erosion can be intensified on construction sites when water wears away land.” This initial disturbance creates conditions that require immediate attention.

Those mountains of soil stockpiles you see on job sites represent another significant sediment source. These mounds sit exposed to the elements, sometimes for extended periods. Without proper controls, a single heavy thunderstorm rolling through Whiteland or New Whiteland can wash away tons of valuable topsoil from these piles—material you’ve already paid to excavate and will need later.

Haul roads and construction entrances become sediment superhighways during wet weather. As trucks and heavy equipment traverse the site, they create compacted pathways where water runs faster and carries more sediment. These same vehicles then track mud onto public roads in Mooresville or Martinsville if proper exit controls aren’t maintained—creating both safety hazards and potential code violations.

The utility trenches we dig for water, sewer, and drainage installations at Patriot Excavating create linear disturbances that can channel water and sediment directly offsite if not properly managed during and after installation.

Central Indiana’s characteristic clay loam soils present particular challenges that make sediment control even more crucial. These soils absorb water slowly (leading to more runoff), hold fine particles that stay suspended in water longer, resist quick revegetation, and form hard crusts when dry that further impede water infiltration.

Understanding these sediment sources is your first step toward developing effective control strategies that protect both your project and our community’s waterways.

Erosion Control vs Construction Site Sediment Control—Why You Need Both

When managing construction sites in Carmel, Fishers, or anywhere in central Indiana, you need both erosion and sediment control working together—like a well-coordinated defense team protecting your site and the surrounding environment.

Erosion control serves as your first line of defense by preventing soil particles from being dislodged in the first place. These proactive measures include erosion control blankets that shield soil from raindrop impact, seeding and mulching that establish vegetation to anchor soil with root systems, surface roughening that creates small ridges to slow water flow, and staged clearing that minimizes exposed soil at any given time.

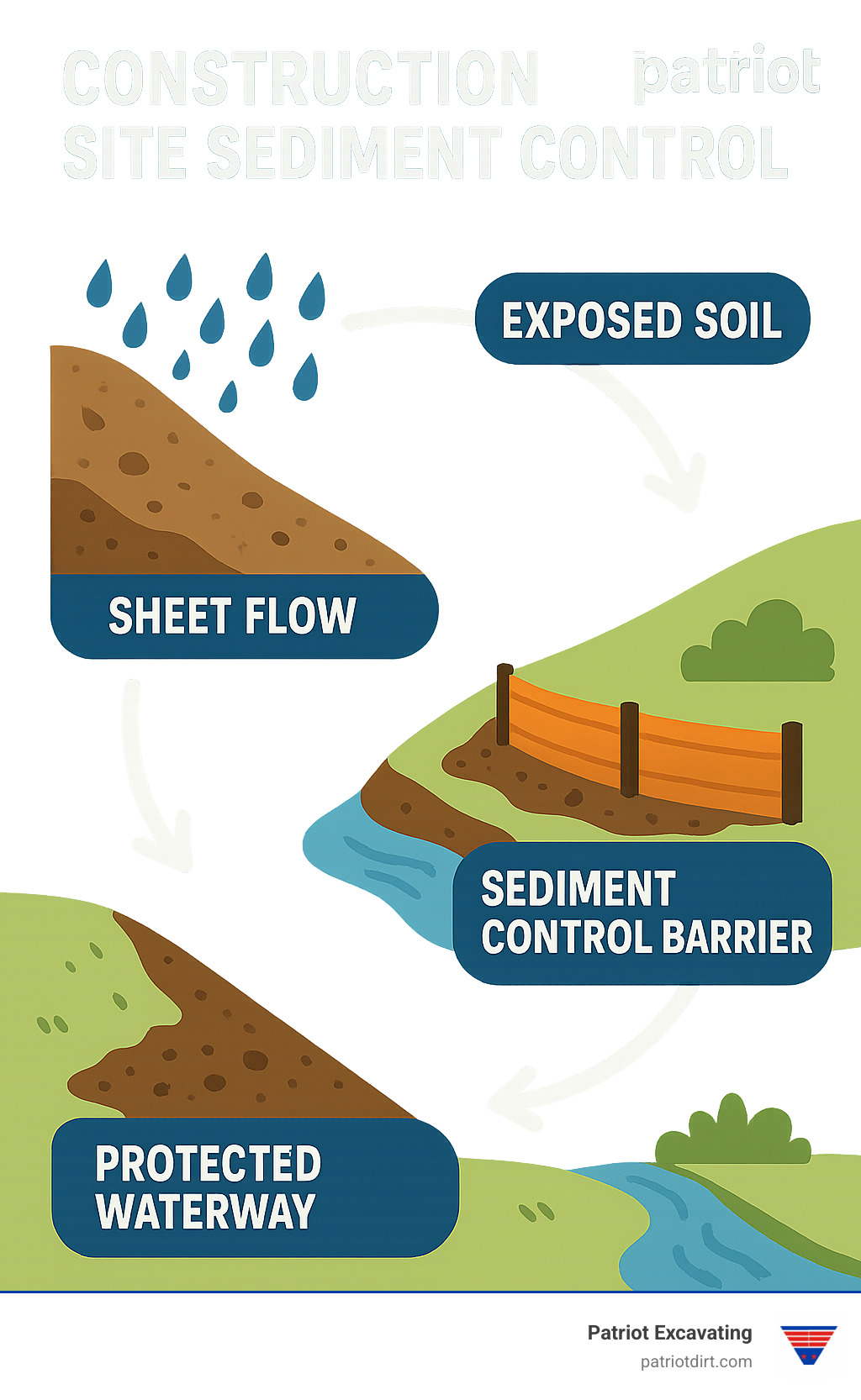

Sediment control, meanwhile, deals with soil particles that have already been dislodged and are being transported by water. These backup systems catch sediment before it leaves your site, including silt fences that filter sediment from sheet flow, sediment basins that allow particles to settle out of stormwater, check dams that slow water velocity in channels, and inlet protection that prevents sediment from entering storm drains.

“Runoff and soil erosion control is more effective and cost-efficient than sediment control,” notes a technical training manual from the construction industry. This dual-defense concept isn’t just nice to have—it’s essential for comprehensive protection.

Here’s how these approaches compare:

| Aspect | Erosion Control | Sediment Control |

|---|---|---|

| Primary function | Prevents soil dislodgment | Captures moving sediment |

| Timing | Implemented first | Secondary defense |

| Cost-efficiency | More cost-effective | More labor-intensive |

| Examples | Vegetation, mulch, blankets | Silt fences, basins, traps |

| Maintenance needs | Usually lower | Typically higher |

| Long-term benefits | Contributes to final stabilization | Temporary during construction |

At Patriot Excavating, we’ve found that implementing both strategies creates a comprehensive system that protects your investment and our environment. On a recent residential development in Avon, we combined hydroseeding on completed slopes with strategically placed silt fences and sediment traps to achieve nearly 95% sediment retention during an unusually wet spring.

Remember: good erosion control reduces the workload on your sediment controls, making the entire system more effective and often reducing maintenance costs throughout your project’s lifecycle.

Permits & Legal Must-Knows for Construction Site Sediment Control

Navigating the regulatory landscape for construction site sediment control in central Indiana might not be the most exciting part of your project, but understanding these requirements can prevent costly delays and penalties.

The cornerstone of federal regulation is the National Pollutant Discharge Elimination System (NPDES) Construction Stormwater General Permit. As the EPA clearly states, “Projects disturbing 1 acre or more of land, or a common plan of development or sale that disturbs greater than 1 acre, require a National Pollutant Discharge Elimination System (NPDES) Construction Stormwater Permit.”

This permit is required for:

- Construction activities disturbing one or more acres of land

- Smaller sites that are part of a larger common plan of development totaling one or more acres

To determine if your project requires coverage, the EPA provides a helpful Construction General Permit Flow Chart: “Do I Need a Permit?” | National Pollutant Discharge Elimination System (NPDES) | US EPA that walks through the decision process with simple yes/no questions about your site’s size and characteristics.

For federal highway projects, additional requirements under 23 CFR 650 Subpart B and [23 U.S.C. 109 Standards 23 U.S.C. 109 Standards(2020) Subsection (g)] apply, mandating that highways funded under Title 23 must minimize erosion and sediment damage to the highway and adjacent properties.

In Indiana specifically, the Indiana Department of Environmental Management (IDEM) administers the Construction Stormwater General Permit program. A crucial component of compliance is developing a Stormwater Pollution Prevention Plan (SWPPP), which must include site description and maps, erosion and sediment control measures, construction sequence, maintenance procedures, and inspection schedules.

Local requirements vary significantly across central Indiana communities:

- Indianapolis enforces the Marion County Stormwater Ordinance with specific requirements for erosion control plans

- Carmel and Fishers have adopted more stringent requirements for sites as small as 10,000 square feet

- Hamilton County requires Rule 5 compliance for all sites disturbing 1 acre or more

When working near wetlands or waterways, additional buffer requirements may apply. These natural buffers serve as the last line of defense before sediment reaches sensitive water bodies.

At Patriot Excavating, we’ve developed expertise in navigating these complex regulations across all central Indiana communities. We work closely with local authorities to ensure all permits are in place before breaking ground, saving our clients from potential compliance headaches.

Remember: The cost of non-compliance can far exceed the investment in proper sediment control measures. Penalties can reach tens of thousands of dollars per violation per day under the Clean Water Act—an expensive lesson you don’t want to learn firsthand.

Selecting & Maintaining BMPs for Indiana Projects

Choosing the right Best Management Practices (BMPs) for your central Indiana construction site requires careful consideration of local conditions and project specifics. At Patriot Excavating, we’ve refined our approach through years of experience across the Indianapolis region.

Site phasing is one of the most effective strategies we employ. By limiting the amount of disturbed area at any given time, we significantly reduce erosion potential. For example, on a recent commercial development in Plainfield, we divided the 15-acre site into three phases, completing rough grading, utility installation, and stabilization of each section before moving to the next.

Understanding local soil conditions is crucial. Central Indiana’s soil maps reveal significant variations even within short distances:

- Glacial till soils in Hamilton County (Carmel, Fishers, Noblesville)

- Clay-rich soils in Hendricks County (Avon, Plainfield, Brownsburg)

- More permeable soils in Johnson County (Greenwood, Franklin, Whiteland)

These soil differences directly impact which BMPs will be most effective for your site.

Weather considerations are equally important. Indiana’s frost depth (typically 30-36 inches) affects winter construction planning, while our region’s thunderstorm frequency—particularly in late spring and summer—necessitates robust sediment control systems that can handle intense rainfall events.

Equipment access and haul-route stabilization must be planned before breaking ground. We typically designate specific routes for heavy equipment, stabilizing these paths with crushed stone to minimize soil disturbance and sediment tracking.

“Proper planning of construction site activities greatly reduces the impact of soil disturbance activities on nearby resources,” notes the Minnesota Pollution Control Agency guidance, a principle that applies equally to our Indiana projects.

Planning Factors: Soil, Slope, Storms

When developing a construction site sediment control plan for projects in Indianapolis and surrounding communities, three critical factors must be considered: soil characteristics, slope conditions, and local storm patterns.

Soil Considerations

Central Indiana soils are classified into hydrologic soil groups that affect how they respond to rainfall:

- Group A: Sandy, well-drained soils (uncommon in our region)

- Group B: Moderately drained soils (found in parts of Hamilton County)

- Group C: Soils with slow infiltration when wet (common throughout Marion County)

- Group D: Clay soils with high runoff potential (prevalent in Hendricks and Johnson Counties)

Understanding your site’s soil group helps determine which sediment control measures will be most effective. For example, sites with Group D soils typically require more robust sediment basins with longer detention times to allow fine clay particles to settle.

Slope Factors

Slope steepness and length dramatically impact erosion potential. The standard recommendation for construction sites is to maintain slopes no steeper than 3H:1V (three feet horizontal for every one foot vertical) whenever possible.

For steeper slopes, we implement more intensive controls:

- Terracing or benching to break up long slopes

- Closer spacing of fiber rolls or silt fences

- More robust erosion control blankets with higher tensile strength

On a recent residential development in Mooresville, we encountered slopes approaching 2H:1V. By installing erosion control blankets and staggered fiber rolls at 15-foot intervals, we successfully prevented sediment loss during construction despite several significant rain events.

Storm Patterns

Central Indiana’s rainfall patterns present unique challenges. Our region experiences:

- Spring thunderstorms with high-intensity rainfall

- Summer convective storms that can drop several inches in hours

- Winter freeze-thaw cycles that can damage BMPs

The rainfall erosivity factor—a measure of the erosion potential of rainfall—peaks in Indiana during late spring and early summer. This means sediment controls must be at their best during this critical period.

“Even well-installed sediment controls allow some of the finest soil particles to pass through,” cautions industry guidance. This is why we at Patriot Excavating often implement redundant systems, especially during high-risk seasons.

For more information on how these factors impact stormwater management, check out our article on Optimize Stormwater Management with Expert Solutions.

Installing Devices Right the First Time

Proper installation of sediment control devices is critical to their effectiveness. At Patriot Excavating, we’ve found that doing it right the first time saves both money and headaches throughout the project lifecycle.

Silt Fencing

Silt fencing is perhaps the most common sediment control device used throughout central Indiana, but it’s also frequently installed incorrectly. For proper installation:

- Trench the bottom 6-12 inches of fabric into the soil and backfill compactly

- Install on the contour, not up and down slopes

- Place support posts on the downhill side, spaced no more than 6 feet apart

- Turn the ends upslope to create a “J-hook” that prevents end-around flow

- Use reinforced fencing for areas receiving concentrated flow

“Silt fence fabric must be buried at least 12 inches,” states EPA guidance, yet we regularly see installations where the fabric is simply laid on the surface, rendering it nearly useless during the first rain event.

For more detailed information on silt fencing, visit our dedicated page on Silt Fencing.

Sediment Traps and Basins

Sizing these structures correctly is essential:

- Sediment traps are appropriate for drainage areas up to 5 acres

- Sediment basins should be used for areas between 5 and 100 acres

When installing sediment basins in the clay-heavy soils common around Brownsburg and Avon, we typically design for 3,600 cubic feet of storage per acre of drainage area to accommodate the slower settling rates of fine particles.

Inlet Protection

Storm drain inlet protection is critical in developed areas like Carmel and Fishers. Effective installation requires:

- Securing filter fabric or commercial products tightly around the inlet

- Providing overflow capacity to prevent flooding during heavy rain

- Ensuring accessibility for maintenance and cleanout

Compost Berms

In environmentally sensitive areas near Monrovia and Martinsville, we often use compost berms as an alternative to silt fence. These berms:

- Should be at least 2.5 feet wide and 1 foot tall

- Can be installed over frozen ground or existing vegetation

- Provide the added benefit of introducing organic matter to the soil

“Cold-weather installations can be performed over snow cover using materials like compost berms and fiber rolls,” notes Minnesota DOT guidance, making these options particularly valuable during Indiana’s unpredictable winters.

Fiber Rolls/Logs

When installing fiber rolls on slopes:

- Place parallel to contours

- Trench in slightly (2-3 inches)

- Stake securely every 4 feet

- Space according to slope steepness (closer spacing on steeper slopes)

- Overlap ends by 12 inches to prevent gaps

As a rule of thumb for spacing: 10 feet for 1H:1V slopes, 20 feet for 2H:1V, 30 feet for 3H:1V, and 40 feet for 4H:1V.

The effectiveness of any sediment control measure depends largely on proper installation. At Patriot Excavating, we train our crews extensively on these techniques to ensure our clients’ sites remain compliant and protected throughout the construction process.

Inspection, Maintenance & Continuous Improvement

Even the best-designed and installed sediment control systems require regular inspection and maintenance to remain effective. At Patriot Excavating, we’ve developed a comprehensive approach to ensure our construction site sediment control measures continue performing throughout the project lifecycle.

Regular Inspection Schedule

For sites in central Indiana, we recommend:

- Weekly inspections of all BMPs

- Additional inspections within 24 hours after every rainfall of 0.5 inches or more

- Special attention during spring thaw conditions when frozen BMPs may fail

“Inspect and maintain all erosion and sediment controls regularly to ensure continued effectiveness,” advises the EPA Construction General Permit. This simple practice can prevent most common sediment control failures.

Maintenance Triggers

Knowing when to maintain your sediment controls is critical. Key triggers include:

- Sediment accumulation reaching 40% of the capacity in basins, traps, or behind silt fences

- Signs of erosion developing around or under control devices

- Damage to silt fence fabric or support posts

- Clogged inlet protection devices

When these conditions are observed, repairs should be completed within 24 hours to maintain compliance with most permits.

Documentation Requirements

Maintaining thorough records is not just good practice—it’s often a permit requirement. For each inspection, document:

- Date and time of inspection

- Name and qualification of inspector

- Weather conditions and rainfall since last inspection

- Locations of discharges of sediment or other pollutants

- Locations of BMPs requiring maintenance

- Locations of BMPs that failed to operate as designed

- Locations where additional BMPs are needed

- Corrective actions required and dates completed

“Routine site inspections are recommended every 7-14 days,” notes industry guidance. These inspections should be documented using standardized forms that can be produced during regulatory inspections.

Continuous Improvement

The most successful projects incorporate lessons learned throughout the construction process. After significant storm events, we evaluate which controls performed well and which didn’t, making adjustments as needed.

For example, on a recent commercial development in Fishers, we noticed that traditional silt fences were failing during intense summer thunderstorms. By upgrading to reinforced silt fence in key areas and adding secondary controls, we significantly improved performance during subsequent rain events.

Proper drainage is fundamental to effective sediment control. For more information on this critical aspect, read our article on The Crucial Role of Proper Drainage: Safeguarding Your Property Against Erosion and Damage.

Maintenance isn’t just about fixing problems—it’s about preventing them. By maintaining your sediment controls proactively, you’ll reduce overall project costs and minimize environmental impacts.

Conclusion & Next Steps

Effective construction site sediment control goes far beyond just checking regulatory boxes. It’s about protecting your investment, keeping your project on schedule, and being a responsible steward of central Indiana’s waterways and natural resources.

Throughout this guide, we’ve seen how the costs of inadequate sediment control can quickly snowball:

Regulatory fines can reach tens of thousands of dollars per day, stop-work orders can derail your carefully planned timeline, and the repairs needed after major erosion events can blow your budget. Not to mention the damage to your reputation in the community when mud washes onto neighboring properties or local streams turn brown after a rain.

At Patriot Excavating, we’ve spent years perfecting our approach to sediment control across Indianapolis and the surrounding communities. Our experience has taught us that an ounce of prevention truly is worth a pound of cure when it comes to managing soil on construction sites.

“The best sediment control plan is the one you never have to fix,” is something I often tell clients. The upfront investment in proper planning and implementation is invariably less than addressing failures after they occur – especially when you factor in potential delays and compliance issues.

When planning your next project in Greenwood, Franklin, or anywhere across central Indiana, I recommend these practical next steps:

Start planning early. The most successful projects incorporate sediment control into the initial site design, not as a last-minute addition. This integration allows for more natural, effective solutions that often cost less to implement and maintain.

Take time to understand your site. Every property has its own unique characteristics – soil types, slope conditions, and natural drainage patterns that should inform your sediment control strategy. What works perfectly in Carmel might need adjustments in Plainfield.

Coordinate your construction schedule with sediment control in mind. By phasing work to minimize the area and duration of soil disturbance, you can dramatically reduce your erosion risk and often simplify your control measures.

Budget appropriately for not just installation, but ongoing maintenance and potential upgrades to your sediment controls. The reality of construction in Indiana means adapting to our unpredictable weather patterns – from spring downpours to winter freeze-thaw cycles.

Partner with Patriot Excavating for your next project. Our team brings decades of local experience implementing effective sediment control measures across the Indianapolis region. We understand both the technical aspects of sediment control and the specific regulatory requirements of your project location.

For more information on services that complement effective sediment control, these resources provide valuable insights:

- Land Grading vs Land Leveling: Key Differences Explained

- Get Your Land Leveled and Graded by Experts

- More info about sewer, water, and drainage services

When mud and sediment stay where they belong, everyone benefits – your project stays on track, your budget remains intact, and our central Indiana waterways stay cleaner. By implementing the strategies we’ve outlined throughout this guide, you’re making a smart investment in your project’s success.

Don’t leave your sediment control to chance. Contact Patriot Excavating today to discuss how our experienced team can help make your next project a success from the ground up – keeping both your site and our community’s waterways clean.